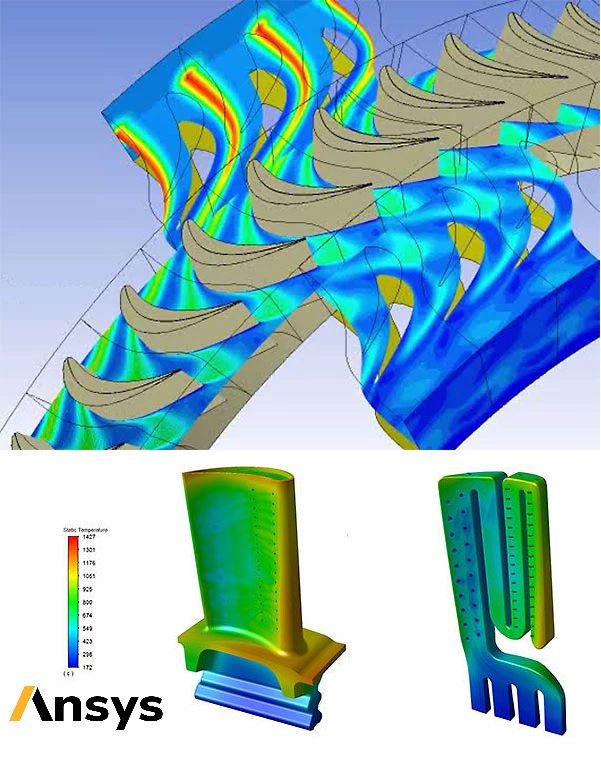

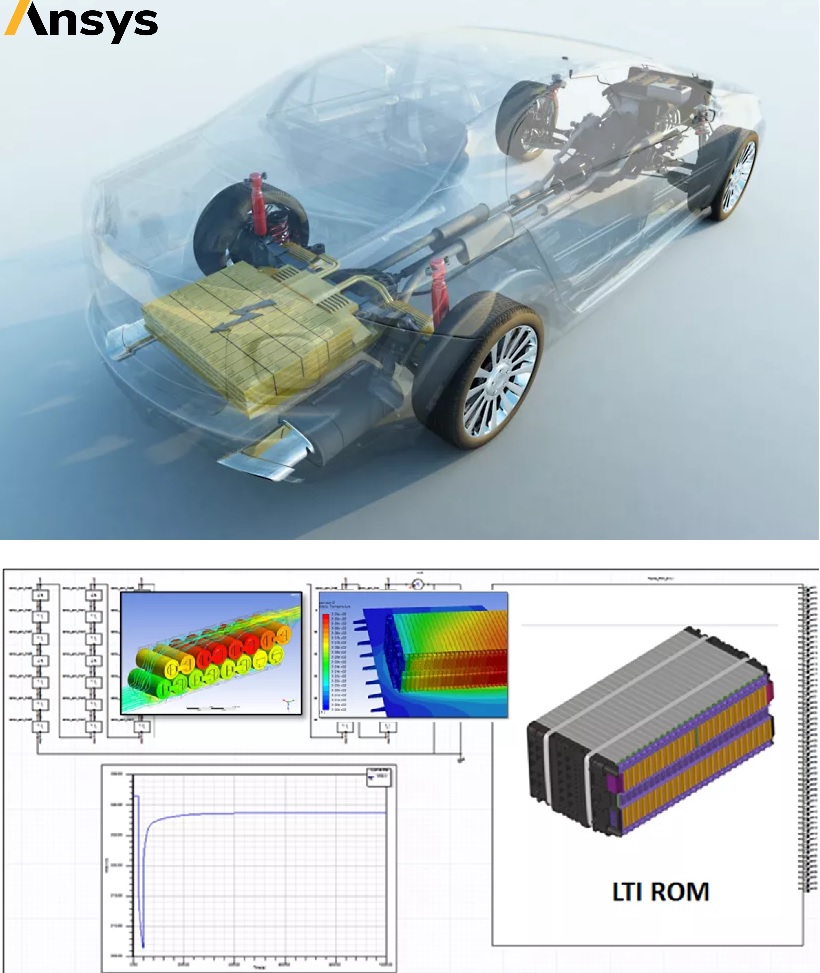

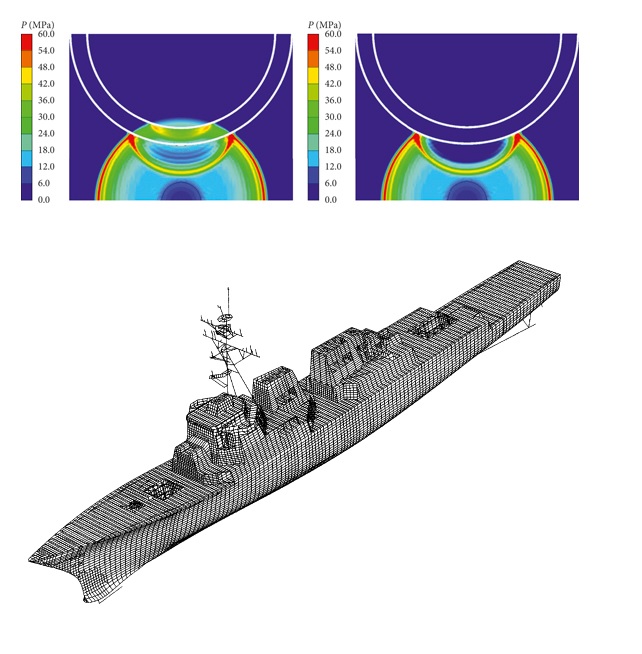

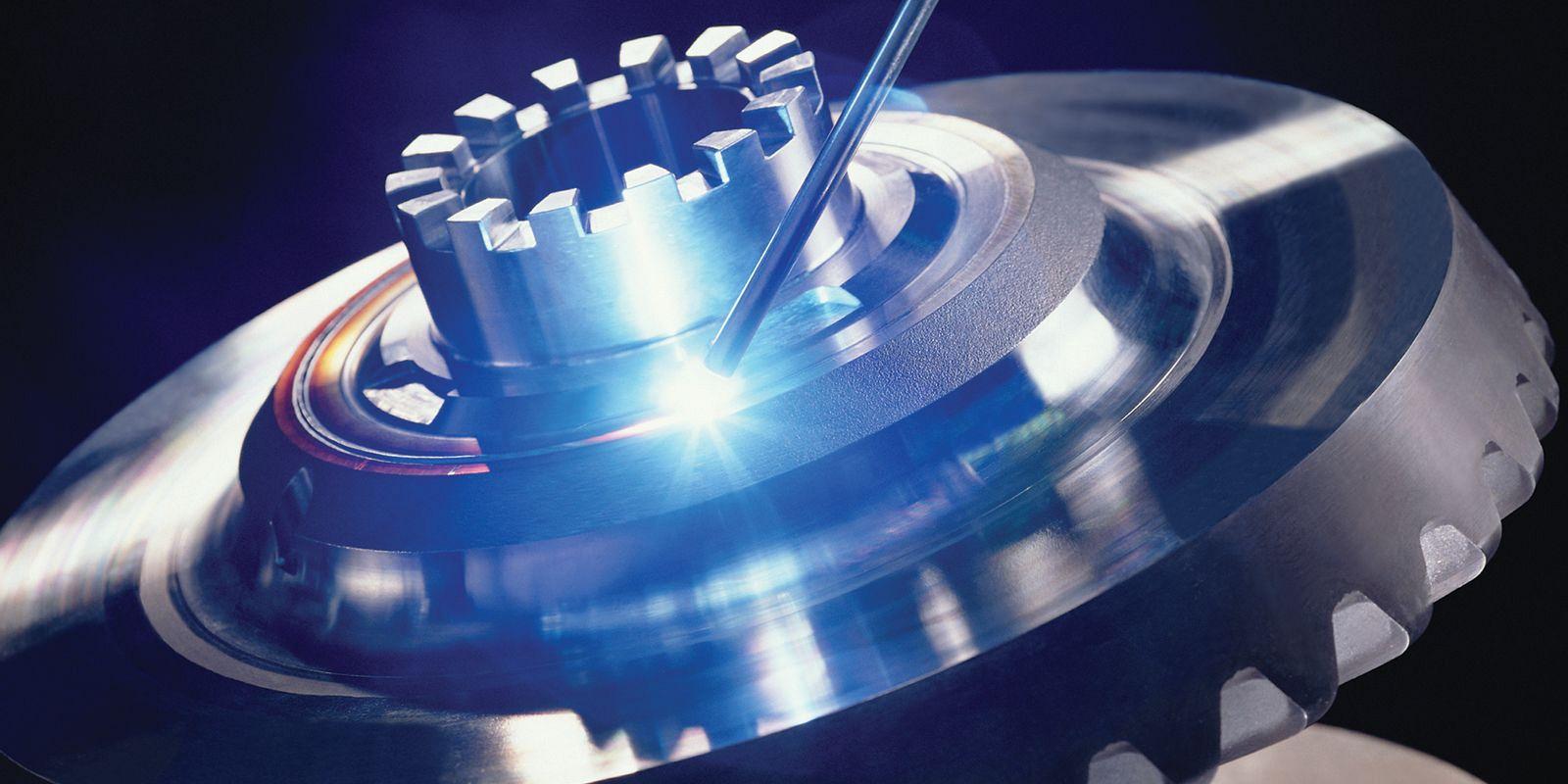

Most machines, especially those that operate under high-heat conditions such as turbines, boilers, and combustors, require strict control of thermal stresses and expansions. These machines are subject to thermal cycling, which can cause differential expansion and contraction between components and lead to premature failure if not properly controlled.

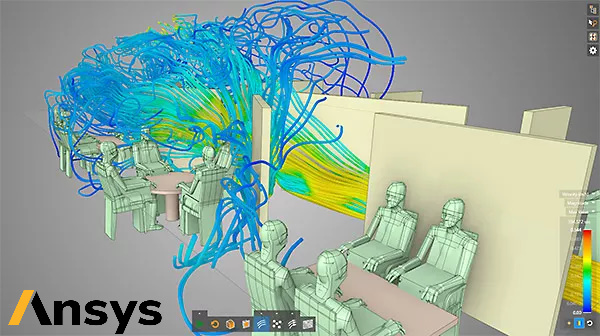

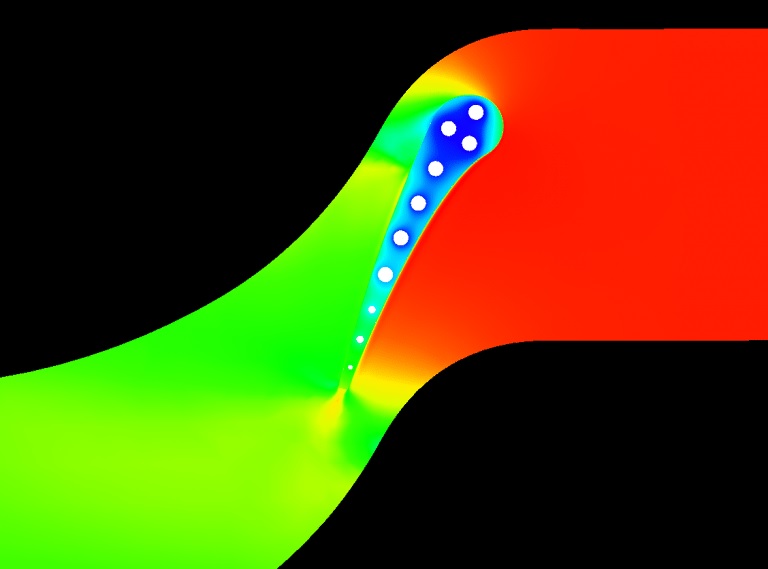

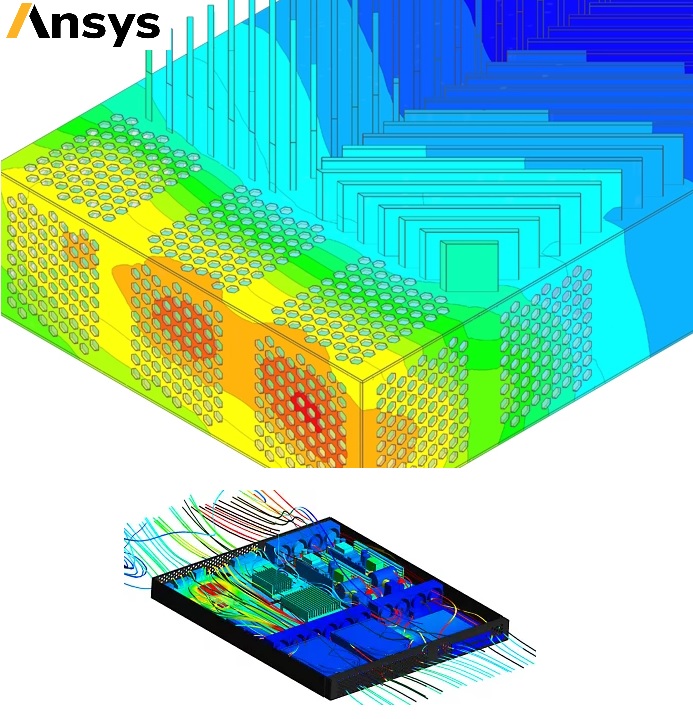

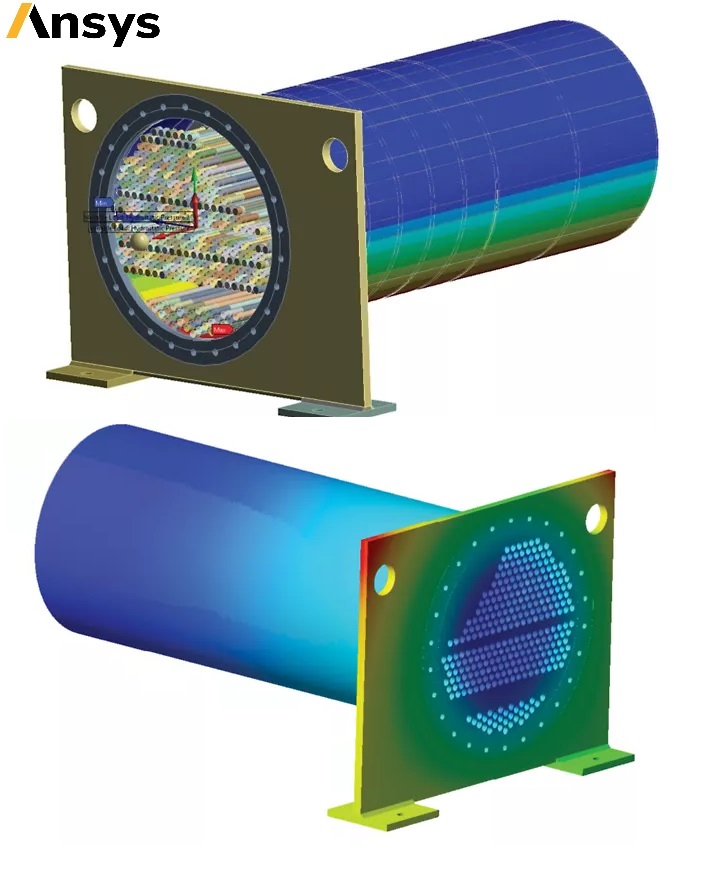

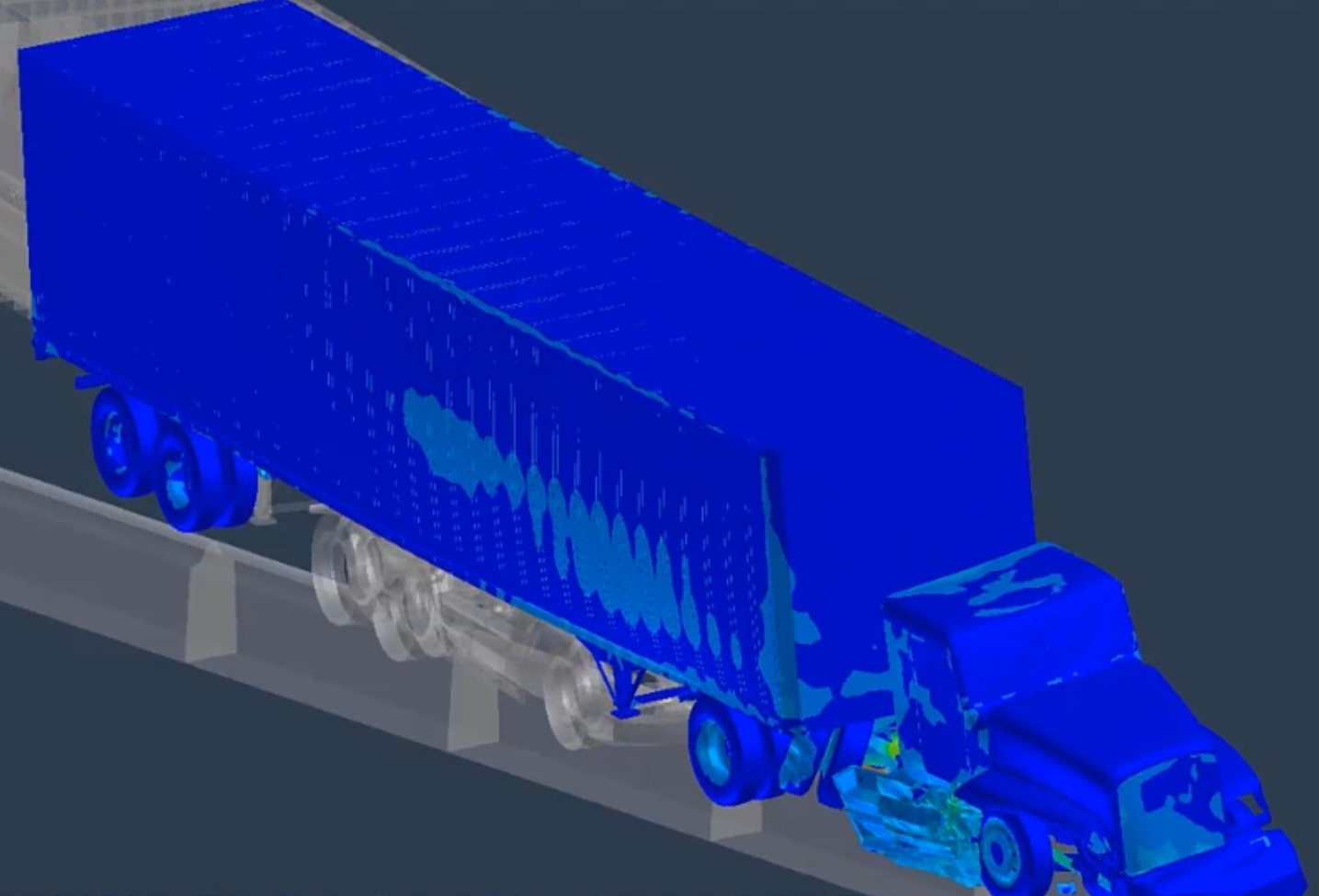

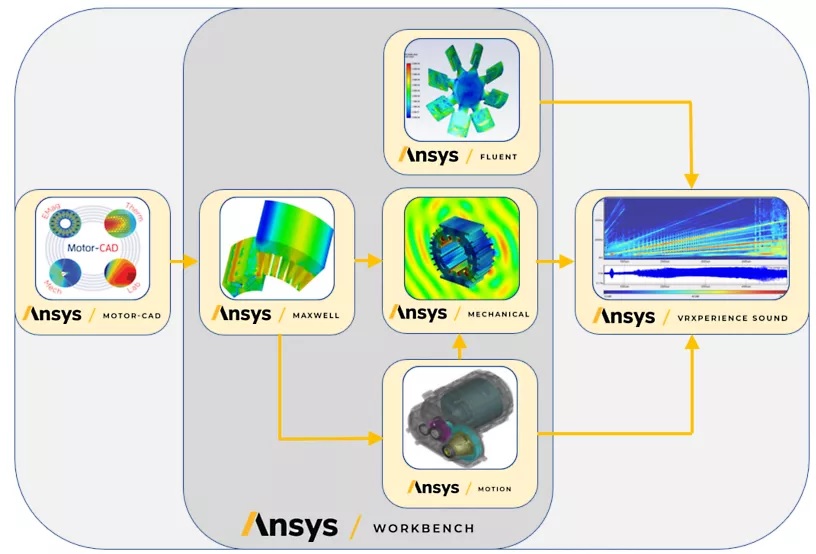

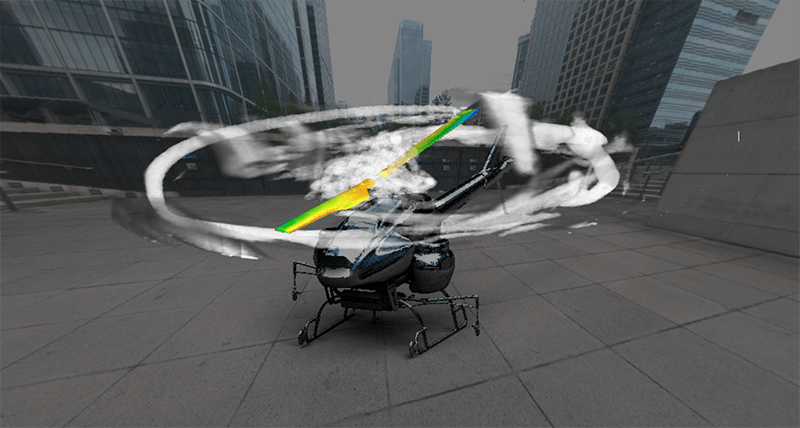

To control thermal stresses and expansions, engineers use CFD and FEA tools to calculate parameters of heat transfer between components. CFD tools such as OpenFoam, Ansys Fluent, and Siemens Star-ccm+ can be used to simulate the flow of fluids and gases within machines, while FEA tools such as Abaqus, Nastran, and LS-DYNA can be used to simulate the response of materials to thermal stresses and deformations.

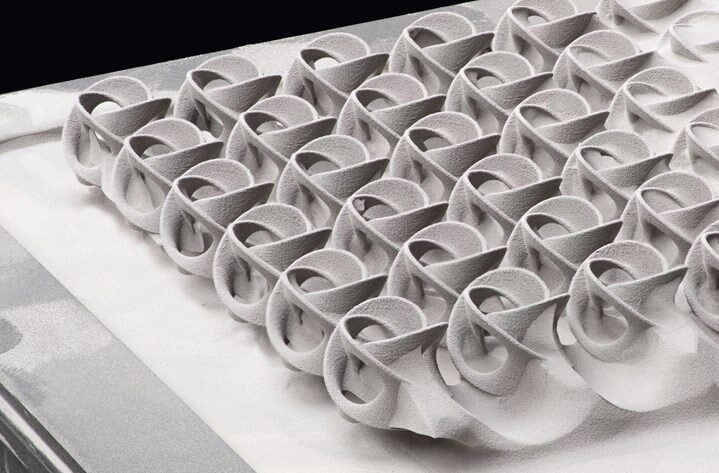

By using these tools, our engineers can optimize the design of machines for thermal performance, identify potential hot spots and areas of stress concentration, and determine the best cooling strategies to reduce thermal stresses and expansions. These simulations can also help to reduce the time and cost associated with physical testing, as well as minimize the risk of failure during operation.